technical

technical

Installation, maintenance, invalidation and correction measures of pulley transmission

1. Correct installation of belt drive: Turn off the power……

MORE

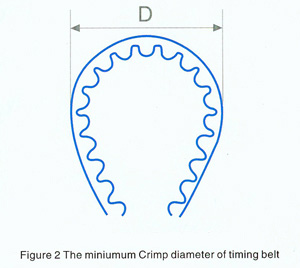

Chart2 The miniumum Crimp diameter of timing belt

Belt type, allowable minimum bending diameter D, mm

MORE

Common problems

Damage situation, causes, and countermeasures of synchronous belts

MORE

Installation, maintenance, invalidation and correction measures of pulley transmission

Installation, maintenance, invalidation and correction measures of pulley transmission

1. Correct installation of belt transmission

(1). Switch off the electricity power, put off the shield and loose the assembly bolt of motor. Move motor to loose belt to a certain degree so that the belt can be take without prying the motor. Remember not to pry the belt.

(2) Take off the old belt to check whether it has any abnormity. Abrasion means there are faults on design of transmission equipment or maintenance.

(3) Choose appropriate belt to replace the old one.

(4) When cleaning belt or pulley, please use rag with little liquid of not-easy volatilization. It is neither correct to dip belt in the detergent or use detergent to scrub belt, nor use sand paper or spiculate articles to scratch in order to wipe off the dirt. Belt should be dry before using.

(5)Check whether the belt has any abnormal abrasion or crack. If the abrasion is beyond normal standard, please change pulley immediately.

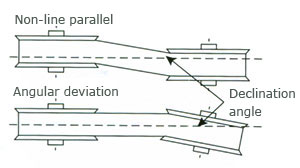

(6) Check whether the pulley is of straight line symmetry. Pulley’s line symmetry is very important to the working of transmission pulley, especially synchronization pulley transmission equipment. (See Picture.1)

Picture 1:belt dissymmetry show

(7) Check others transmission parts, for example, the symmetry between bearings, durability and lubrication, etc.

(8)Never pry or use too strong power when installing new belt on the pulley.

(9) Tighten the central distance of transmission equipment till the tension testing instrument measures that the belt has proper tension. Rotate the main pulley several circles by hand to re-test the tension.

(10).Screw down the assembly bolt to justify the torque. Because when transmission equipment operating, any change of central distance will lead to bad performance of belt, make sure that all transmission assembly parts are screwed down.

(11). Start the equipment and observe the belt performance. Check whether there is abnormal shake, listen whether there is abnormal noise. It is better to turn off the machine and check the status of bearing and motor. If they feel too hot, perhaps the belt is too tight, or the bearings are of dissymmetry or the lubrication is incorrect.

2. Maintenance of belt and pulley

(1). The transmission belt should not be break and bent rapidly.(2). During the storage and transportation process of belt and pulley, avoid sunshine, rain and snow, and avoid them contact acid, halogen, organic solvent steam and other matters which will affect them.

(3). When being stored under normal temperature, generally the temperature is 20-50 centigrade, and the heat resource should be at least one meter away.

(4). Avoid too large weight resulting distortion during storage. Do not fold, press and pile up, do not put the belt on the ground. The belt should be hung on the shelf or put on the shelf flatly.

(5). Pulley finished product should be stored and transported in dry and ventilated circumstance, and it should have rust resistance.

(6). Pulley transmission equipment should have shield, and should be under ventilation and pollution resistance situation.

Chart2 The miniumum Crimp diameter of timing belt

| Type | The minumumcrimp diameter allowed |

| MXL,XXL,T2.5 | 15 |

| XL,T5 AT5 | 15 |

| L,T10 AT10 | 20 |

| H | 40 |

| XH,T20 AT20 | 70 |

| XXH | 100 |

| 3M S2M,S3M,P3M | 15 |

| 5M S4,5M,S5M,P5M | 25 |

| 8M S8M P8M | 40 |

| 14M S14M P14M | 80 |

Common problems

| Injury situation | Reasons | Countermeasures |

| Early broken belt | 1, does not take into account passive round of the inertial force. 2, the excessive load due to accidents or passive round to stop, Thus substantially increasing the power load 3, a small pulley, belt forcibly bending over. |

1, check design. 2, Design Checker. 3, check design changed more than the minimum number of teeth of the pulley. 4, moving, storage, installation operation Should take full and careful. |

| Belt edge wear | 1, parallel axis of closed. 2, bearing rigid inadequate. 3, pulleys ribs bending. 4, pulley diameter smaller than the width belt. |

1, for more on the pulley is positioning. 2, increase the rigidity of bearings, solid and fixed. 3, Ribs amended or replaced. 4, check design. |

| Wear belt tooth surface | 1, the load was too great. 2, belt tension was too great. 3, wear dust infiltration. 4, the relationship between the oil belt to contraction. |

1, improved design. 2, reduced belt tension. 3, improve the environment, increase shields. 4, not belt contaminated with oil or oil belt. |

| Belt-foot drop-off | 1, jumping gear. 2, Shaorong passive wheel bearings and other accidents. |

1, a: load too large. b: Tension early insufficient. c: meshing teeth too small. d: Bearing rigid inadequate. 2, a: check design. b: Tension appropriate adjustments. c: increased pulley diameter, increased meshing teeth. d: replacement bearings, bearings to increase rigidity and fixed solid. |

| With wear and cracking Beijiao | 1, the tension positioning inaccurate. 2, encountered mechanical framework. 3, a long-term low-temperature state. |

1, the amendment tensioner position. 2, check and fix mechanical parts. 3, improving the environment temperature. |

| Softening with Beijiao | 1, high temperature. 2, tensioner to stop. 3, stained with oil. |

1, improve the environment temperature. 2, checking, adjusting tensioner. 3, not due to a change of oil or oil belt. |

| Belt vertical cracks | 1, pulley belt beyond the edge of operation. 2, vol belt on the pulley of the ribs. 3, installation of pulleys, or forcibly dragged into the pulley over Ribs. |

1, adjusted pulley position. 2, enhanced bearing rigid, fixed and solid. 3, a: Ribs removed. b: to shorten the distance between shaft, fitted with belt. c: relax loaded belt tensioner. |

| Zhang part of the anti-fracture | Infiltrated debris or sharp edges of the residue. | Improve the environment, increase shields. |

| Belt contraction | Aniline due to the low point of aromatic oils. | Not stained with oil, use good oil resistance of belt. |

| Running big noise | 1, belt tension too. 2, the two axis parallel inaccurate. 3, greater than the width of belt pulley diameter. 4, load too large. 5, mesh belt and pulley bad. |

1, reduce tension (not prevail jump teeth) 2, the positioning adjustment pulley. 3, check design. 4, check design. 5, check belt and pulley. |

| Tooth wear belt | 1, the load was too great. 2, belt tension was too great. 3, the pulley material bad. 4, wear dust infiltration. |

1, check design. 2, reduce tension. 3, the use of high hardness of the material surface hardening. 4, improve the environment, increase shields. |

| Elongate the look | 1, the short distance between the axis. 2, pulleys soft material. |

1, the distance between the axis adjustment, reinforcing the support bearings. 2, the use of rigid material pulley surface hardening. |