product

product

01

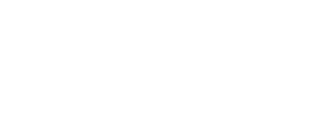

Rack

02

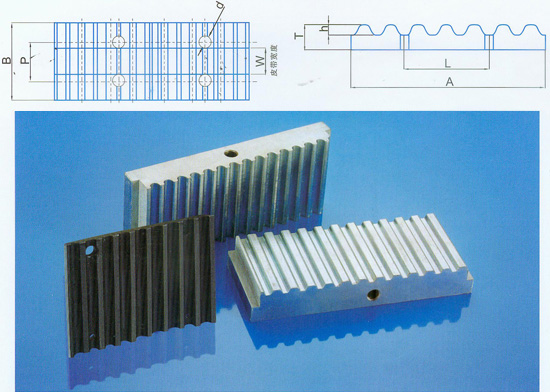

Rack Lever

03

Swelling sets

| Type | Nomal width of the belt | W | A | B | T | h | L | P | d |

| MXL | 025 | 6.4 | 26 | 18 | 4 | 0.51 | 19 | 11 | 3.4 |

| 037 | 9.5 | 22 | 14 | ||||||

| 050 | 12.7 | 26 | 18 | ||||||

| XL | 025 | 6.4 | 36 | 24 | 6 | 1.25 | 25 | 12 | 4.5 |

| 031 | 7.9 | 25 | 14 | ||||||

| 037 | 9.5 | 26 | 16 | ||||||

| 050 | 12.7 | 30 | 20 | ||||||

| L | 050 | 12.7 | 66 | 32 | 8 | 1.9 | 50 | 20 | 5.5 |

| 075 | 19.1 | 38 | 26 | ||||||

| 100 | 25.4 | 46 | 33 | ||||||

| 150 | 38.1 | 58 | 46 | ||||||

| H | 075 | 19.1 | 89 | 38 | 10 | 2.3 | 70 | 26 | 5.5 |

| 100 | 25.4 | 46 | 33 | ||||||

| 150 | 38.1 | 58 | 45 | ||||||

| 200 | 50.4 | 70 | 58 | ||||||

| S2M,P2M | 040 | 4 | 26 | 16 | 4 | 4 | 0.76 | 18 | 3.4 |

| 060 | 6 | 18 | 10 | ||||||

| 010 | 10 | 24 | 15 | ||||||

| 3M,S3M,P3M | 060 | 6 | 21 | 20 | 4 | 4 | 1.14 | 11 | 3.4 |

| 010 | 10 | 25 | 15 | ||||||

| 150 | 15 | 30 | 20 | ||||||

| 5M,S5M,P5M | 100 | 10 | 35 | 26 | 6 | 1.81 | 25 | 16 | 4.5 |

| 150 | 15 | 32 | 21 | ||||||

| 250 | 25 | 42 | 31 | ||||||

| 8M,S8M,P8M | 150 | 15 | 56 | 34 | 8 | 2.85 | 40 | 22 | 5.5 |

| 250 | 25 | 44 | 32 | ||||||

| 300 | 30 | 50 | 37 | ||||||

| 400 | 40 | 60 | 47 | ||||||

| T5,AT5 | 100 | 10 | 35 | 26 | 6 | 1.2 | 25 | 16 | 4.5 |

| 150 | 15 | 32 | 21 | ||||||

| 200 | 20 | 38 | 26 | ||||||

| 250 | 25 | 43 | 31 | ||||||

| T10,AT10 | 150 | 15 | 70 | 34 | 8 | 2.5 | 50 | 22 | 5.5 |

| 200 | 20 | 40 | 27 | ||||||

| 250 | 25 | 44 | 32 | ||||||

| 300 | 30 | 50 | 37 |

| Type | Teeth number rang e | Length |

| MXL | ≤16 | 60 |

| 17~38 | 120 | |

| 39~79 | 160 | |

| ≥80 | 200 | |

| XL | ≤16 | 120 |

| 17~31 | 160 | |

| ≥32 | 200 | |

| L | 10~17 | 160 |

| ≥18 | 200 | |

| H | ≥14 | 200 |

| XH | ≥18 | 200 |

| T2.5 | ≤14 | 60 |

| 17~32 | 120 | |

| 33~62 | 160 | |

| ≥63 | 200 | |

| T5 | ≤16 | 120 |

| 17~32 | 160 | |

| ≥33 | 200 | |

| T10 | 10~16 | 160 |

| ≥17 | 200 | |

| T20 | ≥18 | 200 |

| AT3 | ≤12 | 60 |

| 13~26 | 120 | |

| 27~52 | 160 | |

| ≥53 | 200 | |

| 2M | ≤16 | 60 |

| 17~40 | 120 | |

| 41~78 | 160 | |

| ≥79 | 200 | |

| 3M | ≤12 | 60 |

| 13~26 | 120 | |

| 27~52 | 160 | |

| ≥53 | 200 | |

| S4.5 | ≤18 | 120 |

| 19~35 | 160 | |

| ≥36 | 200 | |

| 5M | ≤17 | 120 |

| 18~32 | 160 | |

| ≥33 | 200 | |

| 8M | 10~16 | 160 |

| ≥17 | 200 | |

| 14M | ≥28 | 200 |

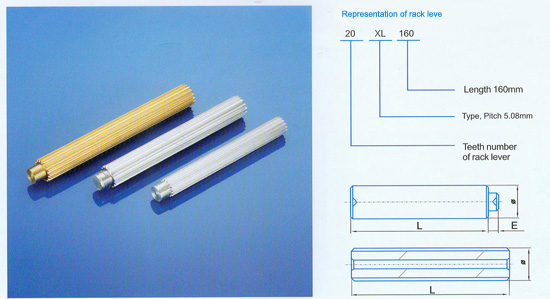

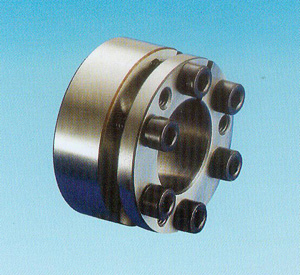

1、Locking assemblies and cone fastening

Suitable for medium and heavy loads, with small radial installation size, convenient and simple. Low surface pressure, low usage cost, allows for larger roughness, and when locked, the hub does not move axially relative to the shaft.

2.The characteristics of conical fastening bush for connecting device:

Taper sleeve a novel mechanical transmission connection component which has been commonly used in the European and American countries. It features as high standard degree, high accuracy, compact structure, easy installation and disassembly and so on. It has tight connection with belt pulley, sprocket, inner cones of other transmission parts through 8°outer cone. It greatly enhances centering precision of various transmission prats. The sizes are of a series of standard designs. Inner hole key-slot has been processed according to ISO standard with fine general-purpose and inter-changeability. It is applicable for all kinds of occasions. When transmission parts have been operated for long time, inner hole and chain slot will possibly be damaged. If such transmission part uses this taper sleeve, normal operation can be recovered after exchanging same specification of taper sleeve! It thus largely increases service life of transmission parts, reduces repair expense and save time at the same time.

Place Taper-lock Bushing and Timing Belt Pulley on the transmission shaft.

Insert screws into cap screw bore tighten the symmetrical screws, Then the pulley grips the shaft firmly though the taper surface of the bushing.

Take binding bolt out entirely. Insert the threaded holes, tighten it. This makes the Bushing easily removed from the Pulley.

Dimension for 1008 to 3030 TAPER-LOCK Bushings

| BUSH NO | Large end diameter | width | Central circle | Bolt specification |

| 1008 | 35.2 | 22.3 | 33.73 | M6*12 |

| 1108 | 38.38 | 22.3 | 36.92 | M6*12 |

| 1210 | 47.62 | 25.4 | 44.44 | M10*16 |

| 1215 | 47.62 | 38.1 | 44.44 | M10*16 |

| 1310 | 50.8 | 25.4 | 47.63 | M10*16 |

| 1610 | 57.15 | 25.4 | 53.97 | M10*16 |

| 1615 | 57.15 | 38.1 | 53.97 | M10*16 |

| 2012 | 69.85 | 31.80 | 66.68 | M12*22 |

| 2517 | 85.73 | 44.5 | 82.55 | M12*22 |

| 2525 | 85.73 | 63.50 | 82.55 | M12*22 |

| 3020 | 107.96 | 50.8 | 101.60 | M16*28 |

| 3030 | 107.96 | 76.20 | 101.60 | M16*28 |

Dimension for 3535 to 5050 TAPER-LOCK Bushings

| BUSH NO | A | B | C | Bolt specification | G |

| 3535 | 127 | 89 | 122.68 | M12*40 | 40° |

| 4040 | 146.05 | 101.60 | 140.72 | M16*45 | 40° |

| 4545 | 161.93 | 114.30 | 155.70 | M20*50 | 40° |

| 5050 | 177.80 | 127 | 170.69 | M20*57 | 40° |

33.STANDARD STOCK BORES METRIC SERIES

| BUSH NO | BORE |

| 1008 | 10、11、12、14、15、16、18、19、20、22、24. |

| 1108 | 10、11、12、14、15、16、18、19、20、22、24、25、28. |

| 1210 1215 | 11、12、14、15、16、18、19、20、22、24、25、28、30、32. |

| 1310 | 14、15、16、18、19、20、22、24、25、28、30、32、35. |

| 1610 1615 | 14、15、16、18、19、20、22、24、25、28、30、32、35、38、40、42. |

| 2012 2017 | 18、19、20、22、24、25、28、30、32、35、38、40、42、45、48、50. |

| 2517 2525 | 20、22、24、25、28、30、32、35、38、40、42、45、48、50、55、60. |

| 3020 3030 | 25、28、30、32、35、38、40、42、45、48、50、55、60、65、70、75. |

| 3525 3535 | 35、38、40、42、45、48、50、55、60、65、70、75、80、85、90. |

| 4030 4040 | 40、42、45、48、50、55、60、65、70、75、80、85、90、95、100. |

| 4535 4545 | 55、60、65、70、75、80、85、90、95、100、105、110. |

| 5040 5050 | 60、65、70、75、80、85、90、95、100、105、110、115、120、125. |

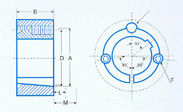

The structural properties:

Z8 Locking assemblies are fit for connecting axis with axis parts so as to transfer torque and axial force.

Mark example:

Z8 locking assemblies:

ID d=20mm, OD d=47mm

Locking assemblies Z8-20*47

JB/T7934-1999

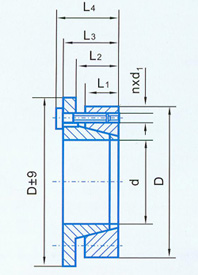

Basic dimensions and parameters of Z8locking assemblies (JB/T7934-1999)

| Basic Size | Rated load | With the expansion set with the surface pressure Pf shaft N/mm2 |

Tighten the screw torque M N-m |

Weight kg |

||||||||

| d | D | L1 | L2 | L3 | L4 | d1 | n | Axial force Ft kN |

Torque Mt kN-m |

|||

| mm | ||||||||||||

| 20 | 47 | 17 | 22 | 28 | 34 | M6 | 5 | 30 | 0.29 | 220 | 17 | 0.25 |

| 22 | 0.32 | 200 | ||||||||||

| 24 | 50 | 0.37 | 200 | 0.27 | ||||||||

| 25 | 6 | 36 | 0.45 | 215 | ||||||||

| 28 | 55 | 0.5 | 200 | 0.32 | ||||||||

| 30 | 0.54 | 190 | 0.35 | |||||||||

| 32 | 60 | 8 | 48 | 0.77 | 215 | 0.37 | ||||||

| 35 | 0.84 | 190 | 0.34 | |||||||||

| 38 | 65 | 0.91 | 195 | 0.4 | ||||||||

| 40 | 0.96 | 190 | 0.38 | |||||||||

| 45 | 75 | 20 | 25 | 33 | 41 | M8 | 7 | 77 | 1.75 | 230 | 41 | 0.63 |

| 50 | 80 | 1.93 | 210 | 0.68 | ||||||||

| 55 | 85 | 8 | 88 | 2.45 | 215 | 0.73 | ||||||

| 60 | 90 | 2.7 | 190 | 0.78 | ||||||||

| 63 | 95 | 28 | 41 | 9 | 100 | 3.18 | 205 | 0.89 | ||||

| 65 | 95 | 33 | 41 | 3.25 | 200 | 0.83 | ||||||

| 70 | 110 | 24 | 30 | 40 | 50 | M10 | 8 | 141 | 5 | 220 | 83 | 1.33 |

| 75 | 115 | 5.25 | 200 | 1.4 | ||||||||

| 80 | 120 | 5.6 | 190 | 1.48 | ||||||||

| 85 | 125 | 9 | 159 | 6.75 | 200 | 1.55 | ||||||

| 90 | 130 | 7.1 | 190 | 1.63 | ||||||||

| 95 | 135 | 10 | 176 | 8.35 | 200 | 1.7 | ||||||

| 100 | 145 | 26 | 32 | 44 | 56 | M12 | 8 | 205 | 10.3 | 210 | 145 | 2.6 |

| 110 | 155 | 11.25 | 190 | 2.8 | ||||||||

| 120 | 165 | 9 | 231 | 13.9 | 210 | 3 | ||||||

| 130 | 180 | 34 | 40 | 52 | 64 | 12 | 308 | 20 | 190 | 4.6 | ||

| 140 | 190 | 54 | 68 | M14 | 9 | 317 | 22.25 | 180 | 230 | 4.9 | ||

| 150 | 200 | 10 | 352 | 26.3 | 190 | 5.2 | ||||||

| 160 | 210 | 11 | 287 | 31 | 190 | 5.5 | ||||||

| 170 | 225 | 44 | 50 | 64 | 79 | 12 | 422 | 35.9 | 150 | 7.75 | ||

| 180 | 235 | 38 | 145 | 8.15 | ||||||||

| 190 | 250 | 15 | 528 | 50.1 | 170 | 9.5 | ||||||

| 200 | 260 | 15 | 52.8 | 160 | 9.9 | |||||||

| 220 | 285 | 50 | 56 | 72 | 88 | M16 | 12 | 587 | 64.5 | 145 | 355 | 13.4 |

| 240 | 305 | 15 | 734 | 88 | 165 | 14.3 | ||||||

| 260 | 325 | 18 | 880 | 114 | 180 | 15.5 | ||||||

| 280 | 355 | 60 | 66 | 84 | 102 | M18 | 16 | 948 | 132 | 150 | 485 | 22.9 |

| 300 | 375 | 18 | 1059 | 159 | 160 | 24.4 | ||||||

| 320 | 405 | 74 | 81 | 101 | 121 | M20 | 18 | 1374 | 220 | 150 | 690 | 36.1 |

| 340 | 425 | 21 | 1603 | 272.5 | 175 | 38.4 | ||||||

| 360 | 455 | 86 | 94 | 116 | 138 | M22 | 18 | 1710 | 308 | 140 | 930 | 46.2 |

| 380 | 475 | 21 | 1995 | 379 | 155 | 55 | ||||||

| 400 | 495 | 1995 | 399 | 150 | 61 | |||||||

Mechanical properties classification is 12.9 grade to Z8 locking assemblies screw.