product

product

01

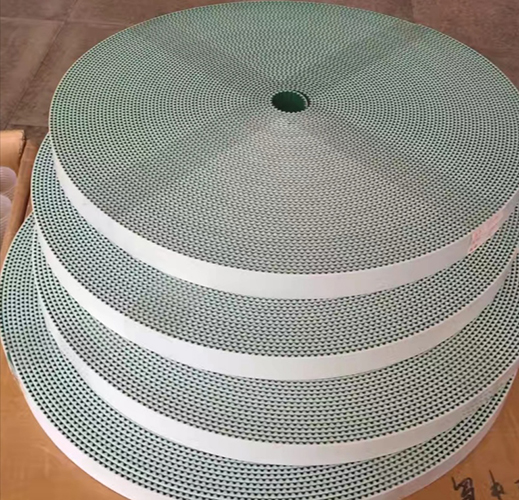

Synchronous Belt

02

Rubber Synchronous Belt

03

Double-sided Timing Belt

04

PU open timing Belt

05

Rubber opening Belt

06

Flour Machine Timing Belt

07

Polyurethane Timing Belts

Synchronous belt drive consists of an endless belt whose Inner surface has equally soaced teeth and of belt wheels which have the corresponding teeh and is a kind of new type belt drive which has synhesized all the good points og belt drive, chain drive and gear drive, while working, the teeth o the belt and the gullets of the gear joggle each other to transmit the motion and the dynamic force.

Synchronous belt drive has such features as exact transmission ratio, non-sllding, constant velocity ratio which can be gained, even motion, absorption ofvibration, little noise,the bia range of transission ratio which can normaly reach 0.98, compacting tructure.The suitability to multi-axis transmission,no need of lubrication,no pollution and so on. Therefore,the product can notmally work well in the places where no pollution is allowed and where the working condition is poor and can widely be used in machinery drives, such industry as automebiies, machine tools, textile, chemical engineering, light industry, mining,indtruments, oil industry and so on as well as all kinds of other machinery drive.

Synchronous belt we produced have a lot of advantages:anti-wearing out, low elongation rate and high strength, resistant to wide temperature range, non-aging, ozone resistant,etc. now we have over 30 types timing belt with more than 2000 specification.And we can supply matched pulleys. All these can meet our customers perfectly . The property of our products have reached or surpassed the internaional standard.

1.Physiconechanical Property of Synchronous Belt

| Ltem | Trapezoid tooth | Atctooth | |||||||||

| XL | L | H | XH | XXH | 3M | 5M | 8M | 14M | 20M | ||

| Tensile strenght N/mm | 80 | 120 | 270 | 380 | 450 | 90 | 160 | 300 | 400 | 520 | |

| Elongatlon | Referenve load | 60 | 90 | 220 | 300 | 360 | 70 | 130 | 240 | 320 | 410 |

| Atreference load | Elongation | 4.0 | |||||||||

| Hardness(Shore A) | 75±5 | ||||||||||

| Adhesion strength of cloth | 5 | 6.5 | 8 | 10 | 12 | - | 6 | 10 | 12 | 15 | |

| Core rope adhesion strength | 200 | 380 | 600 | 800 | 1500 | - | 400 | 700 | 1200 | 1600 | |

| Gear shearing intensith | 50 | 60 | 70 | 75 | 90 | - | 50 | 60 | 80 | 100 | |

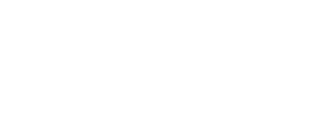

2.Belt length calculation section

| L':2c+1.57(Dp+dp)+(Dp-dp/4c) | Calculation of centre distance between axises |

| L':Approximate pitch line length of belt | C=B+(√B2-2(Dp-dp)2)/4 |

| C:Centredistance between axises | B=L-1.57(Dp+dp) |

| Dp:Pitch diameter of the bigger belt pulley | L:Pitch line length of the belt (mm) |

| dp:Pitch diameter of the smaller belt pulley |

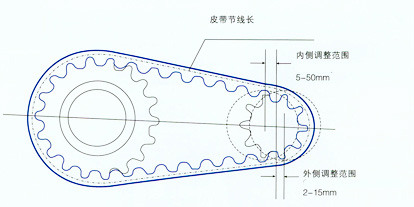

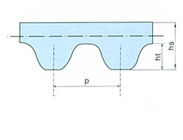

1.Type of rubber synchronous belt & the dimension of section Automotive Timing Belt Dimensions List

| TYPE | Pitch | Tooth height | Belt thickness |

| ZA | 9.525 | 1.91 | 4.10 |

| ZB | 9.525 | 2.29 | 4.50 |

| ZH | 9.525 | 3.50 | 5.50 |

| YH | 8.00 | 3.04 | 5.20 |

| ZR | 9.525 | 3.20 | 5.40 |

| YR | 8.00 | 2.00 | 5.10 |

| ZS | 9.525 | 3.53 | 5.70 |

| YS | 8.00 | 2.95 | 5.20 |

| ZAS | 9.525 | 2.32 | 4.62 |

| ZBS | 9.525 | 2.76 | 5.06 |

| S8MYU | 8.00 | 3.05 | 5.30 |

| FS | 9.525 | 3.05 | 5.35 |

| MY | 8.00 | 3.06 | 5.21 |

| MR | 9.525 | 3.54 | 5.69 |

| RU | 9.525 | 3.44 | 5.40 |

| ZLB | 9.525 | 2.70 | 5.05 |

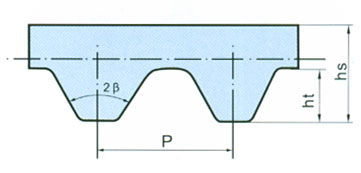

2.T Type industral rubber synchronous belt

| Type | Pitch | Tooth height | Belt thickness | Belt thickness | Teeth number range |

| MXL | 2.032 | 0.51 | 1.14 | 40 | 40-1012 |

| XL | 5.080 | 1.27 | 2.30 | 50 | 30-650 |

| L | 9.525 | 1.91 | 3.60 | 40 | 26-530 |

| H | 12.70 | 2.29 | 4.30 | 40 | 40-472 |

| XH | 22.225 | 6.35 | 11.20 | 40 | 53-200 |

| XXH | 31.750 | 9.53 | 15.70 | 40 | 56-144 |

| T2.5 | 2.5 | 0.7 | 1.30 | 40 | 30-400 |

| T5 | 5 | 1.20 | 2.20 | 40 | 20-444 |

| T10 | 10 | 2.50 | 4.50 | 40 | 26-567 |

| T20 | 20 | 5.00 | 8.00 | 40 | 54-138 |

| AT5 | 5 | 1.20 | 2.70 | 50 | 20-444 |

| AT10 | 10 | 2.5 | 5.00 | 50 | 26-567 |

| AT20 | 20 | 5.00 | 8.00 | 50 | 54-138 |

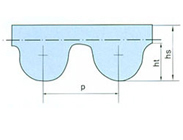

3.Arc tooth industrial rubber synchronous belt

| Type | Type | Pitch | Tooch height | Belt thichness |

| HTD | 3M | 3 | 1.17 | 2.4 |

| 5M | 5 | 2.06 | 3.8 | |

| 8M | 8 | 33.36 | 6.00 | |

| 14M | 14 | 6.02 | 10.00 | |

| 20M | 20 | 8.4 | 13.20 | |

| STPD/STS | S2M | 2 | 0.76 | 1.36 |

| S3M | 3 | 1.14 | 1.9 | |

| S4.5M | 4.5 | 1.71 | 2.81 | |

| S5M | 5 | 1.91 | 3.4 | |

| S8M | 8 | 3.05 | 5.3 | |

| S14M | 14 | 5.3 | 10.2 | |

| RPP/HPPD | P2M | 2 | 0.76 | 1.36 |

| P3M | 3 | 1.15 | 1.9 | |

| P5M | 5 | 1.95 | 3.5 | |

| P8M | 8 | 3.2 | 5.5 | |

| P14M | 14 | 6.00 | 10 |

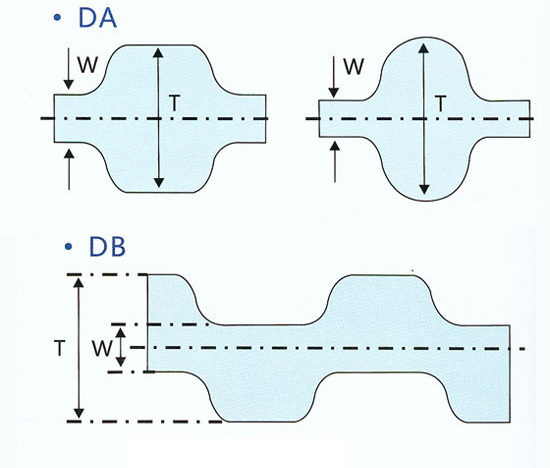

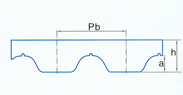

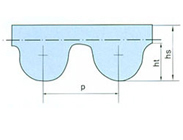

1.Double-sided Timing Belt

·The pitch and tooth profile of double-sided timing belt are same as the single-sided timing belt.

·Double-sided timing belt has two standard forms:

Model DA Symmetrical arrangement of the two-side teeth;

Model DB Staggered arrangement of the two-side teeth.

2.Dimension of double sided timing belt、special profile belt

| Special Profile Belt | Synchronous Belt | ||||

| Type | Pitch length (mm) |

Teeth No | Type | Pitch length (mm) |

Teeth No |

| HTDI200-8M | 1200 | 150 | HTD.DA1200-8M | 1200 | 150 |

| HTDI440-8M | 1440 | 180 | HTD.DA1400-8M | 1400 | 175 |

| STPD1600-8M | 1600 | 200 | HTD.DA1440-8M | 1440 | 180 |

| RPPI760-8M | 1760 | 220 | HTD.DA1600-8M | 1600 | 200 |

| RPPI760-10M | 1760 | 176 | HTD.DA1760-8M | 1760 | 220 |

| RPPI880-10M | 1880 | 188 | HTD.DA1680-8M | 1680 | 210 |

| RPPI920-10M | 1920 | 192 | HTD.DA1920-8M | 1920 | 240 |

| RPPI740-12M | 1740 | 145 | HTD.DA2000-8M | 2000 | 250 |

| RPPI848-12M | 1848 | 154 | HTD.DA2400-8M | 2400 | 300 |

| Pitch Code | Nominal Height | |

| mm | In | |

| D-MXL | 1.53 | 0.06 |

| D-XL | 3.05 | 0.12 |

| D-L | 4.58 | 0.18 |

| D-H | 5.95 | 0.234 |

| D-XH | 15.49 | 0.61 |

| D-XXH | 22.11 | 0.87 |

| D-T2.5 | 2.00 | 0.08 |

| D-T5 | 3.40 | 0.134 |

| D-T10 | 7.00 | 0.275 |

| D-T20 | 13.00 | 0.52 |

| HTD.DA-8M | 8.17 | 0.32 |

1.PU open timing Belt

PU open timing belt is made of ther moplastic polyurethare material and high strength fine steel Wire. It is Of high wear-resistance and strength. It keeps a good condition inb transmission with small production tolerances. PU open timing belt is of the stable transmission, wide application. Long transmission distance ad accurate size.

·It resists ageing. Hydrolysis, ultraviolet ray UVA and ozone.

·Operating temperature: -30℃~+80℃,it can bear max. +110℃ within a short perlod of time.

·Highly oil and grease resistant.

·It resists partial acid and alkali corrosion.

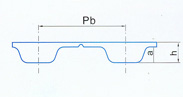

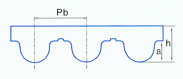

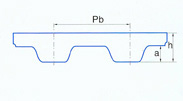

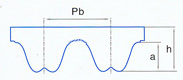

2.PU open Belt Type

| Type | Pitch Pb | Tooth height a | Belt thickness h | STANDARD WIDTH |

| MXL | 2.032 | 0.51 | 1.14 | 025 031 037 050 075 100 |

| XL | 5.08 | 1.27 | 2.3 | 025 031 037 050 075 100 150 200 |

| L | 9.525 | 1.91 | 3.6 | 050 075 100 150 200 300 400 600 |

| H | 12.7 | 2.29 | 4.3 | 050 075 100 150 200 300 400 600 |

| XH | 22.225 | 6.35 | 11.2 | 100 150 200 300 400 600 |

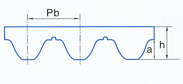

| Type | Pitch Pb | Tooth height a | Belt thickness h | STANDARD WIDTH |

| T2.5 | 2.5 | 0.7 | 1.3 | 6 10 16 25 |

| T5 | 5 | 1.2 | 2.2 | 6 10 16 25 32 50 |

| T10 | 10 | 2.5 | 4.5 | 12 16 25 32 50 75 100 |

| T20 | 20 | 5.0 | 8 | 25 32 50 75 100 115 |

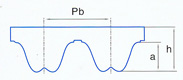

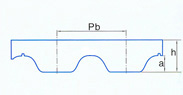

| Type | Pitch Pb | Tooth height a | Belt thickness h | STANDARD WIDTH |

| AT3 | 3 | 1.1 | 1.9 | 10 20 25 50 |

| AT5 | 5 | 1.2 | 2.7 | 6 10 16 25 32 50 |

| AT10 | 8 | 2.5 | 4.5 | 16 25 32 50 75 100 |

| AT20 | 14 | 5.0 | 8 | 25 32 50 75 100 115 |

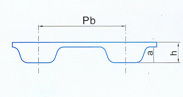

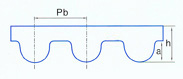

| Type | Pitch Pb | Tooth height a | Belt thickness h | STANDARD WIDTH |

| HTD3M | 3 | 1.17 | 2.4 | 6 9 12 15 25 30 50 |

| HTD5M | 5 | 2.10 | 3.7 | 10 15 25 50 100 150 |

| HTD8M | 8 | 3.38 | 5.6 | 10 15 20 30 50 85 100 |

| HTD14M | 14 | 6.01 | 10 | 25 40 55 85 100 115 |

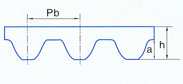

| Type | Pitch Pb | Tooth height a | Belt thickness h | STANDARD WIDTH |

| S3M | 3 | 1.14 | 1.9 | 6 9 12 15 25 30 50 |

| S5M | 5 | 1.85 | 3.35 | 10 15 25 50 100 150 |

| S8M | 8 | 3.05 | 5.3 | 10 15 20 30 50 85 100 |

| S14M | 14 | 5.3 | 10.2 | 25 40 55 85 100 115 |

| Type | Pitch Pb | Tooth height a | Belt thickness h | STANDARD WIDTH |

| RPP5M | 5 | 2.0 | 3.8 | 10 15 25 50 100 150 |

| RPP8M | 8 | 3.2 | 5.4 | 10 15 20 30 50 85 100 |

| RPP14M | 14 | 6 | 10 | 25 40 55 85 100 115 |

1.Rubber Opening Belt

PU open timing belt is made of ther moplastic polyurethare material and high strength fine steel Wire. It is Of high wear-resistance and strength. It keeps a good condition inb transmission with small production tolerances. PU open timing belt is of the stable transmission, wide application. Long transmission distance ad accurate size.

·It resists ageing. Hydrolysis, ultraviolet ray UVA and ozone.

·Operating temperature: -30℃~+80℃,it can bear max. +110℃ within a short perlod of time.

·Highly oil and grease resistant.

·It resists partial acid and alkali corrosion.

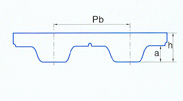

2.Rubber open Belt Type

| Type | Pitch Pb | Tooth height a | Belt thickness h | STANDARD WIDTH |

| MXL | 2.032 | 0.51 | 1.14 | 025 031 037 050 075 100 |

| XL | 5.08 | 1.27 | 2.3 | 025 031 037 050 075 100 150 200 |

| L | 9.525 | 1.91 | 3.6 | 050 075 100 150 200 300 400 600 |

| H | 12.7 | 2.29 | 4.3 | 050 075 100 150 200 300 400 600 |

| XH | 22.225 | 6.35 | 11.2 | 100 150 200 300 400 600 |

| Type | Pitch Pb | Tooth height a | Belt thickness h | STANDARD WIDTH |

| T2.5 | 2.5 | 0.7 | 1.3 | 6 10 16 25 |

| T5 | 5 | 1.2 | 2.2 | 6 10 16 25 32 50 |

| T10 | 10 | 2.5 | 4.5 | 12 16 25 32 50 75 100 |

| T20 | 20 | 5.0 | 8 | 25 32 50 75 100 115 |

| Type | Pitch Pb | Tooth height a | Belt thickness h | STANDARD WIDTH |

| AT3 | 3 | 1.1 | 1.9 | 10 20 25 50 |

| AT5 | 5 | 1.2 | 2.7 | 6 10 16 25 32 50 |

| AT10 | 8 | 2.5 | 4.5 | 16 25 32 50 75 100 |

| AT20 | 14 | 5.0 | 8 | 25 32 50 75 100 115 |

| Type | Pitch Pb | Tooth height a | Belt thickness h | STANDARD WIDTH |

| HTD3M | 3 | 1.17 | 2.4 | 6 9 12 15 25 30 50 |

| HTD5M | 5 | 2.10 | 3.7 | 10 15 25 50 100 150 |

| HTD8M | 8 | 3.38 | 5.6 | 10 15 20 30 50 85 100 |

| HTD14M | 14 | 6.01 | 10 | 25 40 55 85 100 115 |

| Type | Pitch Pb | Tooth height a | Belt thickness h | STANDARD WIDTH |

| S3M | 3 | 1.14 | 1.9 | 6 9 12 15 25 30 50 |

| S5M | 5 | 1.85 | 3.35 | 10 15 25 50 100 150 |

| S8M | 8 | 3.05 | 5.3 | 10 15 20 30 50 85 100 |

| S14M | 14 | 5.3 | 10.2 | 25 40 55 85 100 115 |

| Type | Pitch Pb | Tooth height a | Belt thickness h | STANDARD WIDTH |

| RPP5M | 5 | 2.0 | 3.8 | 10 15 25 50 100 150 |

| RPP8M | 8 | 3.2 | 5.4 | 10 15 20 30 50 85 100 |

| RPP14M | 14 | 6 | 10 | 25 40 55 85 100 115 |

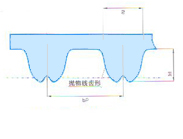

Flour machine synchronous belt parameters

| Special toothed wedge belt for flour machine | |||

| 1760RPP8M-36PK | 1760RPP8M-48PK | 1760RPP8M-28PK | 1760RPP8-34PL |

| 1764RPP12M-34PL | 1440RPP8M-28PK | 1440HTD8M-28PK | 1440RPP8M-48PK |

| 1440HTD8M-48PK | 1778RPP14M-29PL | 1778HTD14M-29PL | 1600RPP8M-24PK |

| 1884RPP12M-34PL | 1552RPP8M-28PK | 1368RPP8M-48PK | 1760RPP10M-26PL |

| 1848RPP12M-34PL | 1880RPP10M-34PL | ||

| Double sided toothed synchronous belt for flour machine | |||

| DA-2400-HTD8M | DA-2000-HTD8M | DA-1600-HTD8M | DA-1400-HTD14M |

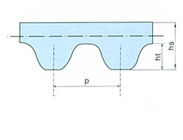

1.T Type industral rubber synchronous belt

| Type | Pitch | Tooth height | Belt thickness | Belt thickness | Teeth number range |

| MXL | 2.032 | 0.51 | 1.14 | 40 | 40-1012 |

| XL | 5.080 | 1.27 | 2.30 | 50 | 30-650 |

| L | 9.525 | 1.91 | 3.60 | 40 | 26-530 |

| H | 12.70 | 2.29 | 4.30 | 40 | 40-472 |

| XH | 22.225 | 6.35 | 11.20 | 40 | 53-200 |

| XXH | 31.750 | 9.53 | 15.70 | 40 | 56-144 |

| T2.5 | 2.5 | 0.7 | 1.30 | 40 | 30-400 |

| T5 | 5 | 1.20 | 2.20 | 40 | 20-444 |

| T10 | 10 | 2.50 | 4.50 | 40 | 26-567 |

| T20 | 20 | 5.00 | 8.00 | 40 | 54-138 |

| AT5 | 5 | 1.20 | 2.70 | 50 | 20-444 |

| AT10 | 10 | 2.5 | 5.00 | 50 | 26-567 |

| AT20 | 20 | 5.00 | 8.00 | 50 | 54-138 |

2.Arc tooth industrial rubber synchronous belt

| Tooth shape code | Type | Pitch | Tooch height | Belt thichness |

| HTD | 3M | 3 | 1.17 | 2.4 |

| 5M | 5 | 2.06 | 3.8 | |

| 8M | 8 | 33.36 | 6.00 | |

| 14M | 14 | 6.02 | 10.00 | |

| 20M | 20 | 8.4 | 13.20 | |

| STPD/STS | S2M | 2 | 0.76 | 1.36 |

| S3M | 3 | 1.14 | 1.9 | |

| S4.5M | 4.5 | 1.71 | 2.81 | |

| S5M | 5 | 1.91 | 3.4 | |

| S8M | 8 | 3.05 | 5.3 | |

| S14M | 14 | 5.3 | 10.2 | |

| RPP/HPPD | P2M | 2 | 0.76 | 1.36 |

| P3M | 3 | 1.15 | 1.9 | |

| P5M | 5 | 1.95 | 3.5 | |

| P8M | 8 | 3.2 | 5.5 | |

| P14M | 14 | 6.00 | 10 |